|

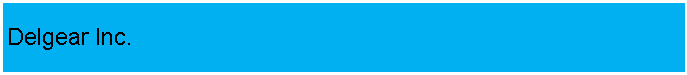

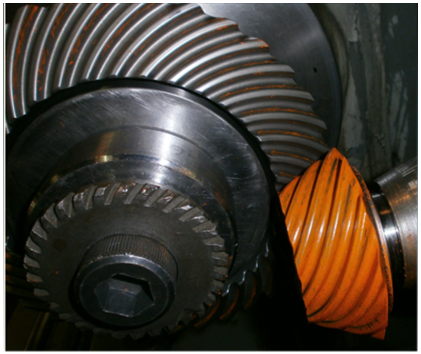

Prototype A 1999 Ford Mustang coupe was chosen to evaluate gear geometry based the Delgear process and software [2014]. The Ford Mustang came with a Ford 7.5 inch, 2.93 ratio hypoid rear end, and a V6 small block. The differential case was disassembled and the mounting features were measured. The figure shows both the rear axle and the gear pair removed from the assembly.

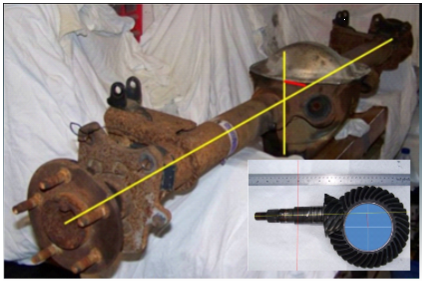

A 3D model for the pinion and gear were created. Below are 3D solid models for each component. Also shown are photographs of the ring and pinion blanks.

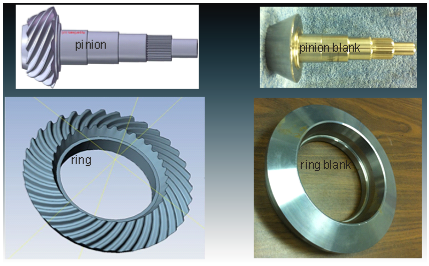

Teeth were added using a standard contour milling process. Below are screen shots of a simulation of the milling process along with photographs of the actual milling of the gear elements.

Ring and pinion after milling and prior to heat treatment together with ring and pinion after heat treatment.

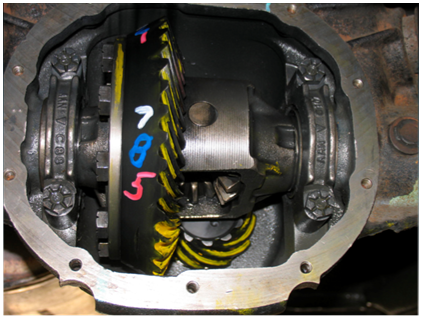

Quality control included inspection and pattern check prior to final gear assembly. Below is the gear set mounted in a gear alignment machine to check the contact pattern.

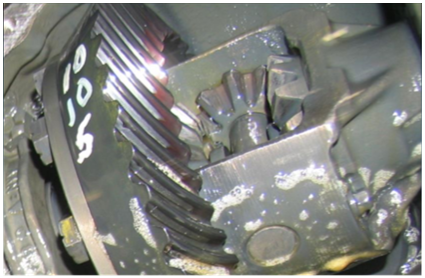

Below is the differential case after the gear pair had been set up during pattern checking. Both pinion assembly and ring carrier assembly were adjusted using standard spacers. As can be seen after assembly, the pattern continues to run parallel to the spiral. A look at the wear of the ring and pinion in application. The below figure shows the freshly washed gears after 5,100 miles of use; note that gear wear remains along the tooth.

Home | About | Examples | Add-ons | Licenses | Prototype | Contact

|